World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

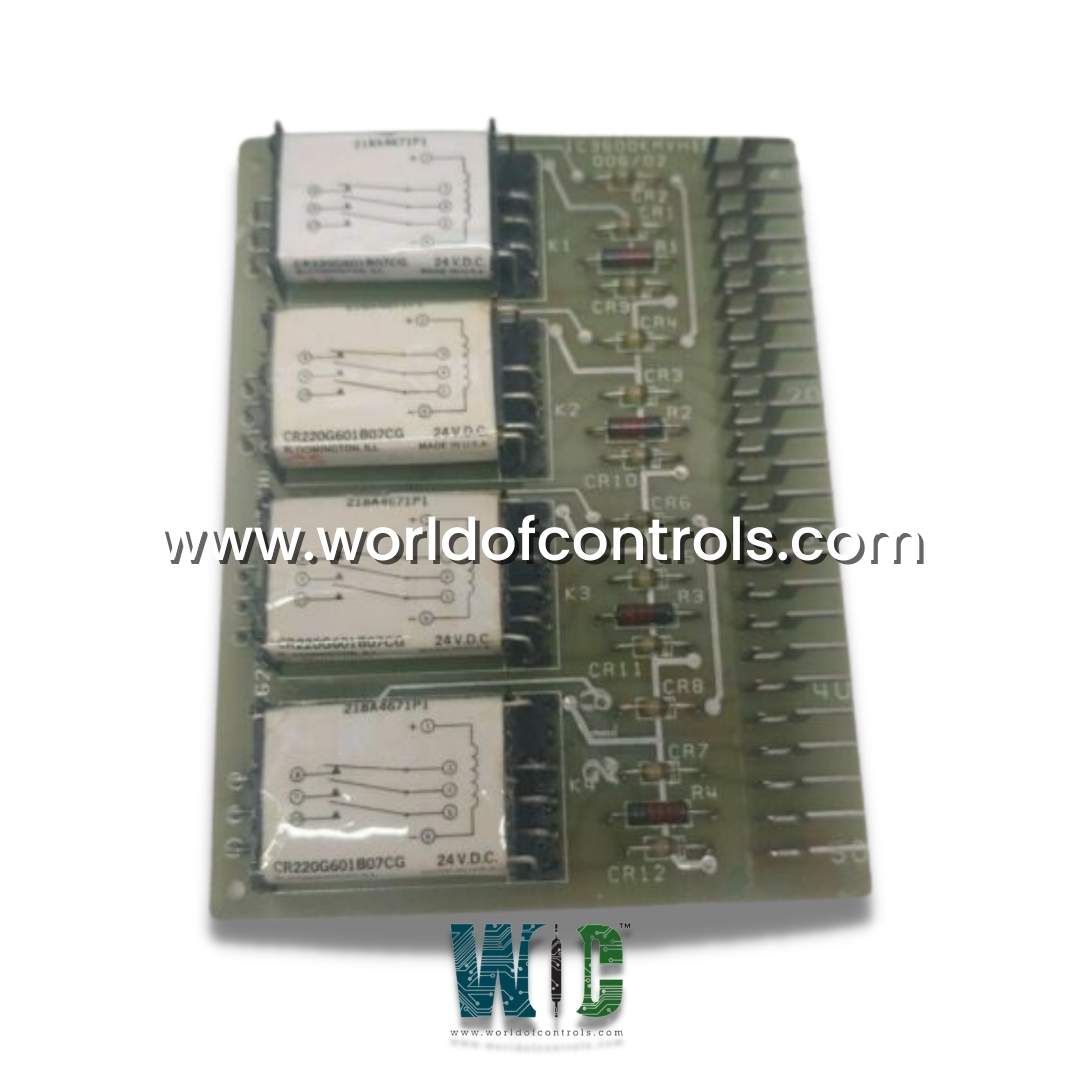

IC3600KMVH1C - Annunciator Relay Card is available in stock which ships the same day.

IC3600KMVH1C - Annunciator Relay Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600KMVH1C - Annunciator Relay Card, contact us and we will get back to you within 24 hours.

Part No: IC3600KMVH1C

Manufacturer: General Electric

Function: Annunciator Relay Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600KMVH1C is an Annunciator Relay Card developed by GE. It is a part of Mark I and II control system. These control systems were among the earliest digital control solutions for gas turbines, enabling effective monitoring, automation, and safety functionalities for industrial gas turbines. The Mark I and II systems have largely been replaced by newer Speedtronic systems, such as Mark IV, Mark V, and Mark VI. These newer systems offer enhanced functionality, increased processing power, and greater integration capabilities, significantly improving turbine efficiency, reliability, and control precision.

The Mark I and Mark II systems were designed to automate and streamline gas turbine operations, which traditionally required significant manual intervention. The card, as part of these systems, enabled efficient and centralized monitoring and control, thus making gas turbines more dependable and reducing downtime. These early systems were groundbreaking in their approach to digital control, giving operators far more insight and command over turbine operation than was previously possible.

As the demand for increased performance, scalability, and reliability grew, GE introduced the Mark IV, Mark V, and eventually the Mark VI and Mark VIe Speedtronic systems. These newer systems incorporated more sophisticated digital processing capabilities, allowing for advanced data analytics, remote monitoring, and enhanced fault tolerance. Some key advancements include:

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600KMVH1C?

It is an Annunciator Relay Card developed by GE.

Is it possible to find replacement parts for the Relay Card?

Yes, replacement parts and refurbished cards are available through WOC specializing in legacy GE Speedtronic system components.

What are the main benefits of upgrading from Mark I/II to a newer Speedtronic system?

Upgrading provides several benefits, including improved processing power, enhanced diagnostic features, remote monitoring capabilities, and better integration with plant control systems. Newer systems (like Mark VI) also offer enhanced safety and performance, making them more suitable for modern turbine operations.